The European Commission is considering whether to regulate GHG emissions related to the entire life cycle of materials used in the construction sector. 72 case studies show that reducing embodied carbon makes economic sense.

This report presents 72 case studies on how reducing embodied carbon in construction will impact the investment costs of buildings and infrastructure.

Taking embodied carbon into account in the design stage is the most effective way to reduce both embodied carbon and costs. On average across all design case studies, embodied carbon reductions of 41% could cut costs by 9% compared to the business-as-usual case (BaU). The broad scope of the case studies enables us to extend the conclusions to residential buildings, commercial buildings and infrastructure.

The case studies per individual intervention confirm that ample cost-effective embodied carbon mitigation potential exists. Stakeholders in the construction value chains should be incentivised to make whole-life embodied carbon reductions an important criterion in building design, the selection of construction materials and the selection of construction methods (for an overview of all case studies, see this blog post).

Embodied carbon in global construction is estimated at 10%

Buildings and infrastructure require energy to operate, which contributes to greenhouse gas (GHG) emissions. In buildings, this involves primarily heating, cooling and lighting. However, the construction, maintenance, renovation and eventual decommissioning of buildings and infrastructure also contribute to GHG emissions.

When we consider GHG emissions associated with a building’s construction materials and its full life cycle (excluding operational emissions from its use phase), they are referred to as embodied carbon. Buildings operation in the EU is responsible for 36% of GHG emissions from the energy sector. The construction sector in the EU is responsible for around 50% of all extracted materials, and over 35% of EU waste generation. Clear figures on embodied carbon in EU construction are lacking but at a global level this is estimated at 10% of all GHG emissions.

Ample potential exists for cost-effective embodied carbon emission reduction

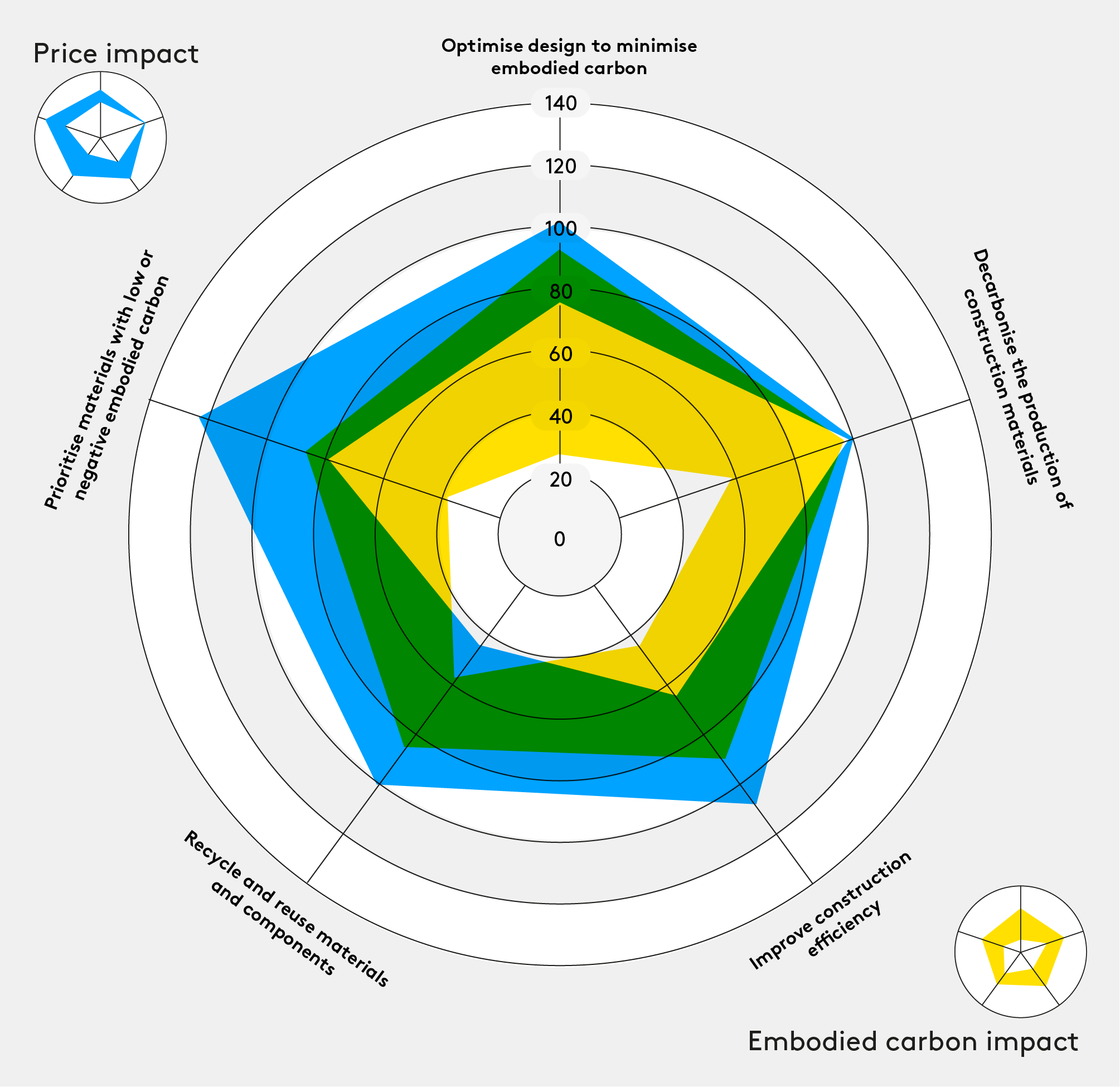

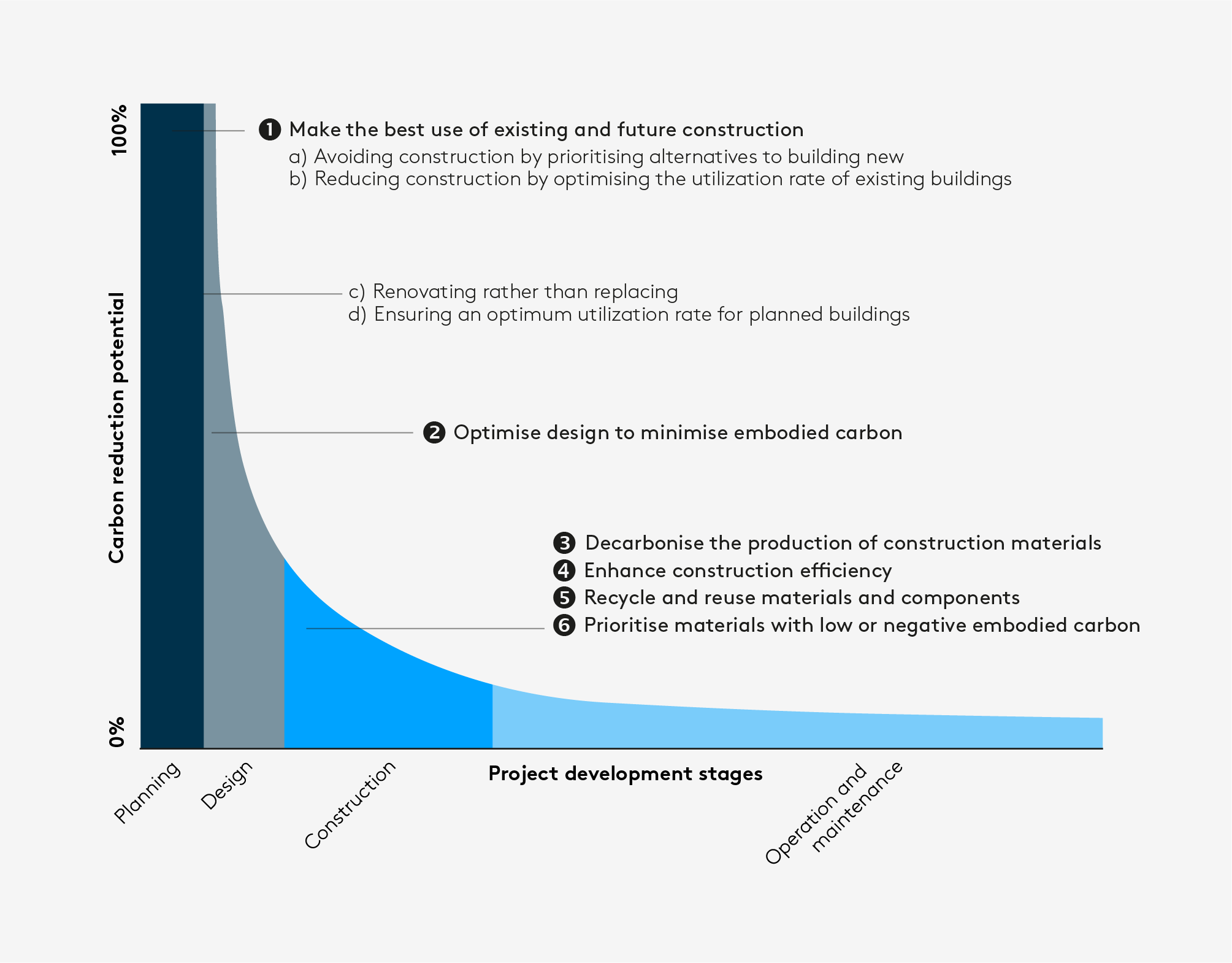

The research shows that for new construction and renovation most GHG abatement potential lies in the planning and design stages. The data are categorised into six interventions to reduce embodied carbon emissions (Figure 1). They are inspired by circular economy principles.

In this figure, 100 represents no change. Thus, reducing embodied carbon would have no impact on price. Values below 100 indicate that carbon reduction or cost savings are realistic. All sources of quantitative data on embodied carbon come from historic real life or hypothetical case studies (primarily 2017-2022). Projections towards 2050 have been left out.

1. Make the best use of existing and future construction

The potential for GHG mitigation is greatest at the planning stage, where the approaches chosen can seek to avoid or, at least, minimise new construction.. Since this involves avoiding construction, rather than reducing its impact, the embodied carbon reduction potential of this interventions has not been quantified.

2. Optimise building design to minimise embodied carbon

The case studies indicate that tailored design very effectively can reduce both embodied carbon and costs for both buildings and infrastructure. On average, across all design case studies, embodied carbon reductions of 41% could cut costs by 9% compared to the business-as-usual case (BaU).

3. Decarbonise the production of construction materials

The embodied carbon mitigation potential of this group of interventions is large but requires major capital investments. Expanding the capacity of renewable energy to power steel mills requires substantial amounts of materials, each with its own carbon footprint. That downside of this intervention is often ignored.

Combining the potential to mitigate embodied carbon in the production of cement, steel and glass with available technologies could achieve a 42% reduction for a reference house. Decreasing embodied carbon beyond 50% is possible only in the long run and would require a combination of major capital investments, new technologies and design optimisation.

4. Improve construction efficiency

Waste avoidance and an average of 22% embodied carbon reduction represent most of the mitigation impact of off-site construction. Cost reductions of 15% were also reported, together with improved working conditions. Off-site construction can also improve the efficiency of renovation and retrofitting.

5. Recycle and reuse materials and components

Both recycling and reuse can reduce the embodied carbon of new construction by around 32%, with a 19% cost reduction on average. Emission reductions of over 95% were recorded for individual construction materials.

6. Prioritise materials with low or negative embodied carbon

Finally, material substitution may offer the greatest opportunity to make deep reductions in embodied carbon, with an average reduction of 38%. However, the cost case is less convincing. Based on all sources, cost savings and increases average out to be neutral.

The results of the six interventions examined make a compelling case that ample opportunities exist for cost effective embodied carbon reductions. This conclusion echoes the UK Green Building Council, which stated that “embodied carbon management may be seen as a proxy for cost management.” The variation in the results supports the conclusion that the climate and cost effectiveness of the options are case specific, but the many options available indicate that one or more cost-effective embodied carbon mitigation measures are likely available for each case.

Policy recommendations

Avoiding or minimising new construction altogether remains the most effective way to reduce embodied carbon emissions in the construction sector. Strategies based on that objective optimise the utilization rate of existing buildings and avoid vacancies, ensure that new construction reflects actually need, and involve renovating rather than replacing buildings. They should be part of any effort to reduce and avoid emissions from this sector. When new construction is unavoidable, most of the GHG mitigation and sequestration potential lies in the design stage. The stakeholders who design buildings or define the design criteria should be an important policy target.

It is encouraging that embodied carbon reduction can reduce investments costs for new construction, renovations and retrofits. However, it creates the risk of a rebound effect, whereby efficiency gains lead to cost savings, which in turn lead to increased consumption or use. For example, consumers might use those cost savings to enlarge floor area. Such rebound effects would prevent absolute emission reductions across construction value chains and should be considered when designing effective emission reduction policies.

To avoid stranded assets, the EU needs to right-size large capital investments in construction sector value chains, particularly when the investments themselves involve a substantial amount of embodied carbon. For example, decarbonising the heavy industries that produce construction materials requires switching from fossil fuels to low-carbon alternatives, such as hydrogen or electricity from renewable energy sources. This requires substantial capital investments in those industries, as well as in increased renewable energy generation and distribution capacity. All these investments in heavy industry and the energy sector have their own embodied carbon impact. This should be considered when scaling and prioritising the options to reduce the embodied carbon impact of the construction sector. However, it is often ignored in long-term models of roadmaps intended to reduce the GHG footprint of industrial products. Understanding cross-sectoral impacts and properly tying interventions in material flows to GHG emissions across sectors requires a systems approach and closer collaboration between the energy system and material analysis communities.

Finally, the use of wood, flax, hemp, cellulose, wood fibre or cork-based insulation materials may help to transform the construction sector into a net carbon sink if emissions along the value chains of these natural construction products are managed properly. Although

forestry stakeholders indicate that forest production can be expanded while strengthening biodiversity, competing land use activities, as well as relevant planetary boundaries, should be considered when planning to use forestry- or agriculture based construction materials at scale.

Photo by Ricardo Gomez Angel on Unsplash